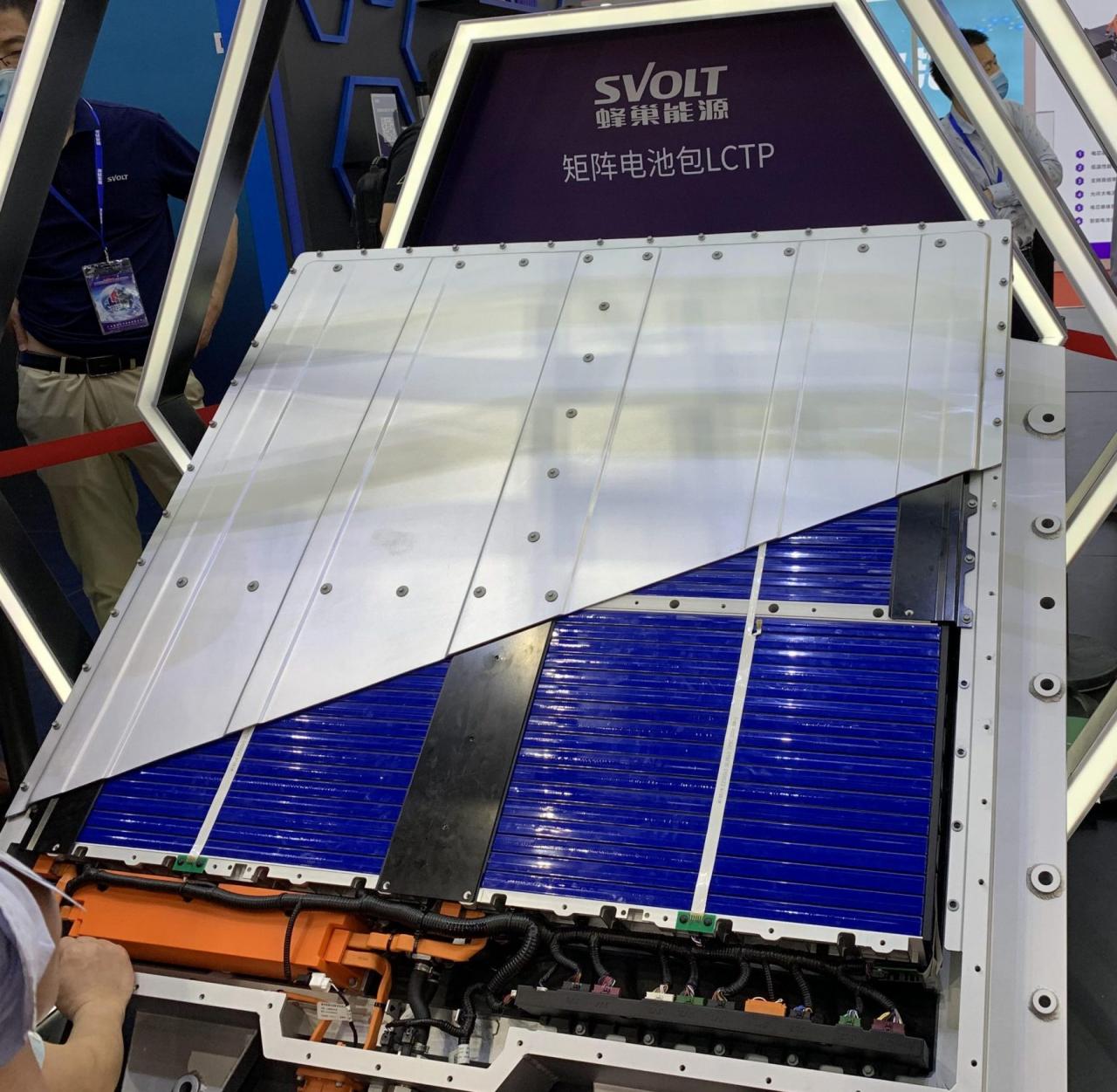

On July 21st, the 2022 World Power Battery Conference kicked off in Yibin, Sichuan. As the first world-class power battery industry event held in my country, this conference brought together experts and leading companies in the global power battery industry chain. Discussions on hot topics such as forward-looking technological breakthroughs, supply chain ecological construction, application model innovation, and recycling.

Unsurprisingly, the phenomenon of skyrocketing raw material prices for power batteries has become the focus of the conference. Many guests are “full of firepower” and bluntly stated that “the huge fluctuations in power battery prices have affected the healthy development of the new energy vehicle industry.”

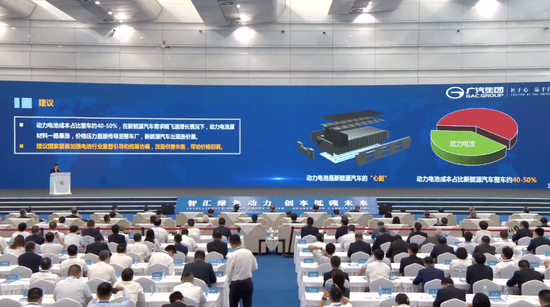

Zeng Qinghong, chairman of GAC Group, revealed that the current cost of power batteries accounts for 40%, 50%, and 60% of the total cost of automobiles, and is increasing. In this regard, he said with a smile: “Am I not working for the Ningde era now?”

Zeng Qinghong’s suggestion of strengthening the supervision and guidance of the battery industry at the national level has aroused widespread responses in the industry. On the same day, Yin Tongyue, chairman of Chery Automobile, forwarded relevant news in the circle of friends, as if to “solidarity” in the air.

The power battery enters the TWh era

In the first half of this year, China’s auto sales were 12.057 million, down 6.6% year-on-year, but new energy vehicle sales reached 2.6 million, up 115% year-on-year, and the penetration rate was as high as 21.6%. Driven by demand, the installed capacity of power batteries has been on the rise. From January to June, the installed capacity of power batteries in my country totaled 110.1GWh, a year-on-year increase of 109.8%.

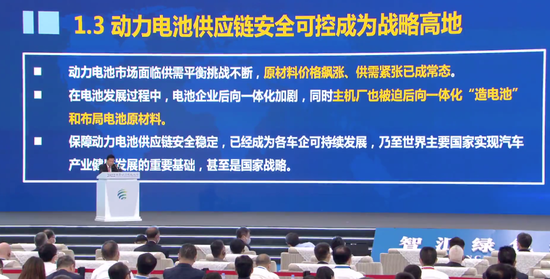

Zeng Qinghong said that the current safety and controllability of the power battery supply chain has become a strategic highland for the industry. Global battery demand is expected to enter the TWh era in 2023.

Zeng Qinghong, Chairman of GAC Group (Photo source: Photo courtesy of the company)

Zeng Yuqun, chairman of CATL, also believes that the full electrification of the automotive industry is accelerating and will soon enter the TWh era.

Zeng Yuqun revealed that the global market share of CATL reached 34% in the first half of this year. At present, the company’s products have covered 55 countries and regions around the world, and the shipment of power batteries has exceeded 400GWh. One out of every three electric vehicles in the world is equipped with batteries from CATL.

Zeng Yuqun, Chairman of Ningde Times (Source: Screenshot of the live broadcast)

High prices make the middle and lower reaches of the industry distressed

Although the market demand space for power batteries is very clear, both power batteries and car companies are distressed by the high price of raw materials. In the past year, the prices of raw materials such as lithium carbonate and lithium hexafluorophosphate have skyrocketed, and the price of some lithium battery materials has risen by more than 8 times, which has put a certain pressure on the middle and lower reaches of the industry chain. A round of “price hikes”.

From the recent performance forecasts released by a number of A-share listed companies, one or two can be seen. Benefiting from the skyrocketing price of power battery raw materials, upstream mining companies have made a lot of money, and their performance in the first half of the year has collectively increased.

The days of car companies are obviously not so easy. Although the sales of new energy vehicles of some car companies continue to rise, their profitability is still limited. Zeng Qinghong revealed that at present, all new energy vehicle manufacturers except Tesla are in a state of loss.

“We are even considering buying lithium mines.” Zeng Qinghong said that ensuring the safety and stability of the power battery supply chain has become an important basis for the sustainable development of various auto companies, and even the healthy development of the auto industry in major countries in the world, and even a national strategy.

(Image source: Live screenshot)

Therefore, he suggested that the national level should strengthen the supervision, guidance and overall coordination of the battery industry, improve the imbalance between supply and demand, and coordinate the price of power battery raw materials to return to a reasonable range.

(Image source: Live screenshot)

Regarding the skyrocketing price of raw materials for power batteries, Zeng Yuqun believes that there is a certain amount of hype, and the high price has brought short-term troubles to the industry chain. In his view, mineral resources are not the bottleneck of industrial development. The proven lithium resource reserves can produce 160TWh lithium batteries, which is fully enough to produce power batteries and energy storage batteries needed by the world.

“Batteries are different from oil, they are gone after use. Most of the materials in the battery can be reused. At present, our nickel-cobalt-manganese recovery rate has reached 99.3%, and lithium has reached more than 90%.” Zeng Yuqun predicted After 2035, we could meet a significant portion of the market by recycling material from decommissioned batteries, he said. At the same time, enterprises can also improve the development and utilization level of my country’s advantageous minerals through a series of technologies such as lithium extraction from ceramic soil.

There are still multiple challenges in the industry chain

Zeng Yuqun said that there are currently three challenges in the power battery industry chain. First, consumers put forward higher requirements for enterprises’ R&D capabilities; second, large-scale delivery puts forward higher requirements for enterprises’ manufacturing capabilities; third, industrial in-depth development puts forward higher requirements for enterprises. The service force puts forward higher requirements.

Focusing on the above three aspects, currently from power battery companies to car companies are stepping up their efforts. For example, a number of battery technologies developed by GAC Group are centered on improving user experience, including sponge silicon anode chip battery technology, super fast charging technology, and magazine battery system safety technology, etc. Pain points in the security field.

For a leading power battery company such as CATL, continuously improving battery performance is obviously one of the core issues. Zeng Yuqun believes that material system innovation is the key to improving battery performance. At present, CATL has used algorithms to find the binding points between various material elements and the optimal balance point between positive electrodes, negative electrodes, electrolytes and diaphragms, and then analyzes the data on real vehicles, so as to make positive progress in product development. Feedback to precipitate a variety of solutions.

It is reported that the research and development of sodium-ion batteries is based on the complementarity of computing power, algorithms and data.

In terms of structural innovation, both BYD and CATL have come up with their own plans. Zeng Yuqun said that the Kirin battery recently launched by CATL does not require a “stack battery” and can achieve a range of 1,000 kilometers. Next year, there will be a number of new models using Kirin batteries on the market.

Original link:https://www.energy-storage.com.cn/274.html